VOCs廢氣處理去除廢氣的方法是什么?

在工業(yè)領(lǐng)域,揮發(fā)性有機(jī)化合物(VOCs)廢氣的治理始終是環(huán)保技術(shù)的核心課題。面對成分復(fù)雜、濃度波動大的廢氣特征,單一處理技術(shù)往往難以滿足多維度需求。通過深入分析多種工藝的技術(shù)特性與實(shí)踐案例,可發(fā)現(xiàn)VOCs廢氣處理需構(gòu)建技術(shù)協(xié)同體系,其核心在于根據(jù)廢氣屬性與治理目標(biāo)實(shí)現(xiàn)精準(zhǔn)匹配。

In the industrial field, the treatment of volatile organic compounds (VOCs) waste gas has always been a core issue in environmental protection technology. Faced with the complex composition and large concentration fluctuations of exhaust gases, a single treatment technology often fails to meet multidimensional needs. Through in-depth analysis of the technical characteristics and practical cases of various processes, it can be found that the treatment of VOCs waste gas requires the construction of a technical collaborative system, whose core lies in achieving precise matching based on the properties of the waste gas and the treatment goals.

吸附技術(shù)作為應(yīng)用廣泛的物理處理方法,其效能發(fā)揮高度依賴吸附劑特性。活性炭纖維對苯系物等小分子污染物展現(xiàn)出優(yōu)異的吸附性能,尤其在電子制造行業(yè)的低濃度廢氣處理中,可實(shí)現(xiàn)90%以上的凈化效率。對于含酯類、酮類化合物的涂裝廢氣,沸石轉(zhuǎn)輪憑借其規(guī)則孔道結(jié)構(gòu),能有效避免水分競爭吸附問題。吸附技術(shù)的局限性在于飽和吸附劑的再生環(huán)節(jié),蒸汽脫附產(chǎn)生的含VOCs冷凝液需納入危廢管理體系,這直接增加了處理成本。

Adsorption technology, as a widely used physical treatment method, is highly dependent on the characteristics of the adsorbent for its effectiveness. Activated carbon fibers exhibit excellent adsorption performance for small molecule pollutants such as benzene derivatives, especially in the treatment of low concentration exhaust gases in the electronic manufacturing industry, achieving purification efficiency of over 90%. For coating exhaust gases containing esters and ketones, zeolite rotors, with their regular pore structure, can effectively avoid water competition adsorption problems. The limitation of adsorption technology lies in the regeneration process of saturated adsorbents, and the VOCs containing condensate generated by steam desorption needs to be included in the hazardous waste management system, which directly increases the processing cost.

催化燃燒技術(shù)通過貴金屬催化劑降低反應(yīng)溫度,將VOCs轉(zhuǎn)化為無害物質(zhì)。在石油化工行業(yè),該技術(shù)處理苯類廢氣時(shí),起燃溫度可控制在300℃以下,熱回收效率超過90%。催化劑中毒是制約其穩(wěn)定運(yùn)行的關(guān)鍵因素,含氯有機(jī)物會導(dǎo)致催化劑活性位點(diǎn)不可逆失活。針對這一問題,部分企業(yè)采用雙催化劑床層設(shè)計(jì),通過在線監(jiān)測反應(yīng)器進(jìn)出口濃度變化,實(shí)現(xiàn)催化劑的梯級利用與智能切換。

Catalytic combustion technology uses precious metal catalysts to reduce the reaction temperature and convert VOCs into harmless substances. In the petrochemical industry, this technology can control the ignition temperature below 300 ℃ and achieve a heat recovery efficiency of over 90% when treating benzene waste gas. Catalyst poisoning is a key factor restricting its stable operation, and chlorinated organic compounds can cause irreversible deactivation of the active sites of the catalyst. In response to this issue, some enterprises adopt a dual catalyst bed design, which achieves cascade utilization and intelligent switching of catalysts by monitoring the concentration changes at the inlet and outlet of the reactor online.

生物處理技術(shù)開辟了綠色治理新路徑。在污水處理場惡臭氣體處理中,生物滴濾塔通過優(yōu)化填料級配與營養(yǎng)液配方,使甲苯降解率穩(wěn)定在85%以上。該技術(shù)對環(huán)境溫濕度的敏感性要求配套溫控系統(tǒng),在北方地區(qū)冬季運(yùn)行時(shí),需投入額外能耗維持菌種活性。對于成分復(fù)雜的化工廢氣,生物法常作為預(yù)處理單元,與吸附或燃燒技術(shù)形成組合工藝。

Biological treatment technology has opened up a new path for green governance. In the treatment of odorous gases in sewage treatment plants, the biological drip filtration tower stabilizes the degradation rate of toluene at over 85% by optimizing the packing material grading and nutrient solution formula. The sensitivity of this technology to environmental temperature and humidity requires a temperature control system, which requires additional energy consumption to maintain bacterial activity during winter operation in northern regions. For chemical waste gases with complex components, biological methods are often used as pre-treatment units, combined with adsorption or combustion technologies to form a combined process.

低溫等離子體技術(shù)在處理含硫雜環(huán)化合物時(shí)表現(xiàn)出獨(dú)特優(yōu)勢。某醫(yī)藥中間體生產(chǎn)企業(yè)實(shí)踐表明,該技術(shù)對噻吩類廢氣的分解率可達(dá)80%,但需嚴(yán)格控制輸入功率以避免氮氧化物副產(chǎn)物生成。配套活性炭吸附裝置可有效攔截臭氧等中間產(chǎn)物,確保尾氣達(dá)標(biāo)排放。

Low temperature plasma technology exhibits unique advantages in treating sulfur-containing heterocyclic compounds. Practice in a pharmaceutical intermediate production enterprise has shown that this technology can decompose thiophene waste gas up to 80%, but strict control of input power is required to avoid the generation of nitrogen oxide by-products. The supporting activated carbon adsorption device can effectively intercept intermediate products such as ozone, ensuring that the exhaust emissions meet the standards.

膜分離技術(shù)為高價(jià)值VOCs回收提供了新選擇。在油氣回收領(lǐng)域,聚酰亞胺中空纖維膜組件可將汽油蒸氣濃度濃縮至原始值的10-20倍,回收油品純度滿足再利用標(biāo)準(zhǔn)。膜污染問題通過定期反沖洗與化學(xué)清洗可得到有效控制,但膜材料成本仍占初期投資的40%以上。

Membrane separation technology provides a new option for high-value VOCs recovery. In the field of oil and gas recovery, polyimide hollow fiber membrane modules can concentrate gasoline vapor concentration to 10-20 times the original value, and the purity of the recovered oil meets the reuse standards. The problem of membrane fouling can be effectively controlled through regular backwashing and chemical cleaning, but the cost of membrane materials still accounts for more than 40% of the initial investment.

實(shí)際工程中,技術(shù)組合方案展現(xiàn)出顯著優(yōu)勢。某包裝印刷企業(yè)采用“沸石轉(zhuǎn)輪吸附+催化燃燒”工藝,將非甲烷總烴排放濃度從800mg/m3降至30mg/m3以下,運(yùn)行成本較傳統(tǒng)活性炭吸附工藝降低35%。在化工園區(qū)綜合治理項(xiàng)目中,“冷凝+膜分離+催化燃燒”三級處理系統(tǒng)實(shí)現(xiàn)溶劑回收率92%,年經(jīng)濟(jì)效益超過800萬元。

In practical engineering, the technology combination scheme has shown significant advantages. A certain packaging and printing enterprise adopts the "zeolite rotary adsorption+catalytic combustion" process to reduce the concentration of non methane total hydrocarbon emissions from 800mg/m 3 to below 30mg/m 3, reducing operating costs by 35% compared to traditional activated carbon adsorption processes. In the comprehensive management project of the chemical industrial park, the three-stage treatment system of "condensation+membrane separation+catalytic combustion" achieved a solvent recovery rate of 92% and an annual economic benefit of over 8 million yuan.

VOCs廢氣處理技術(shù)的選擇需建立三維評估體系:技術(shù)維度需匹配污染物特性與排放標(biāo)準(zhǔn),經(jīng)濟(jì)維度要核算全生命周期成本,管理維度要考慮操作復(fù)雜度與安全風(fēng)險(xiǎn)。未來,隨著智能監(jiān)測與數(shù)字孿生技術(shù)的應(yīng)用,處理系統(tǒng)將向自適應(yīng)調(diào)節(jié)方向發(fā)展,通過實(shí)時(shí)響應(yīng)廢氣參數(shù)變化,動態(tài)優(yōu)化工藝組合,實(shí)現(xiàn)環(huán)境效益與經(jīng)濟(jì)效益的雙贏。

The selection of VOCs waste gas treatment technology requires the establishment of a three-dimensional evaluation system: the technical dimension needs to match the characteristics of pollutants and emission standards, the economic dimension needs to account for the full life cycle cost, and the management dimension needs to consider operational complexity and safety risks. In the future, with the application of intelligent monitoring and digital twin technology, processing systems will develop towards adaptive regulation, dynamically optimizing process combinations through real-time response to changes in exhaust gas parameters, and achieving a win-win situation between environmental and economic benefits.

本文由VOCs廢氣處理友情奉獻(xiàn).更多有關(guān)的知識請點(diǎn)擊:http://m.52campus.cn我們將會對您提出的疑問進(jìn)行詳細(xì)的解答,歡迎您登錄網(wǎng)站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://m.52campus.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

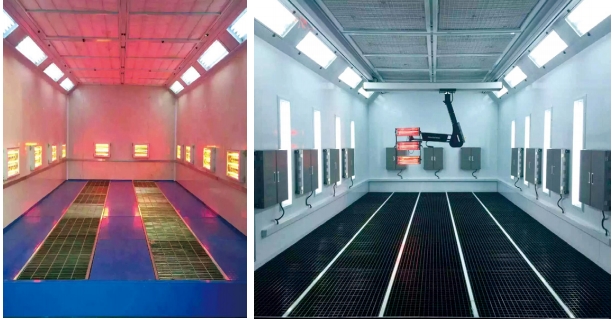

上一篇:工業(yè)涂裝流水線安裝流程:從藍(lán)圖到實(shí)景的精密演繹

下一篇:機(jī)器人涂裝線:重塑制造業(yè)的“顏值革命”

魯公網(wǎng)安備 37142502000144號

魯公網(wǎng)安備 37142502000144號